C9 hydrocarbon petroleum resins HY-9100RM designed for road markings

Product Name

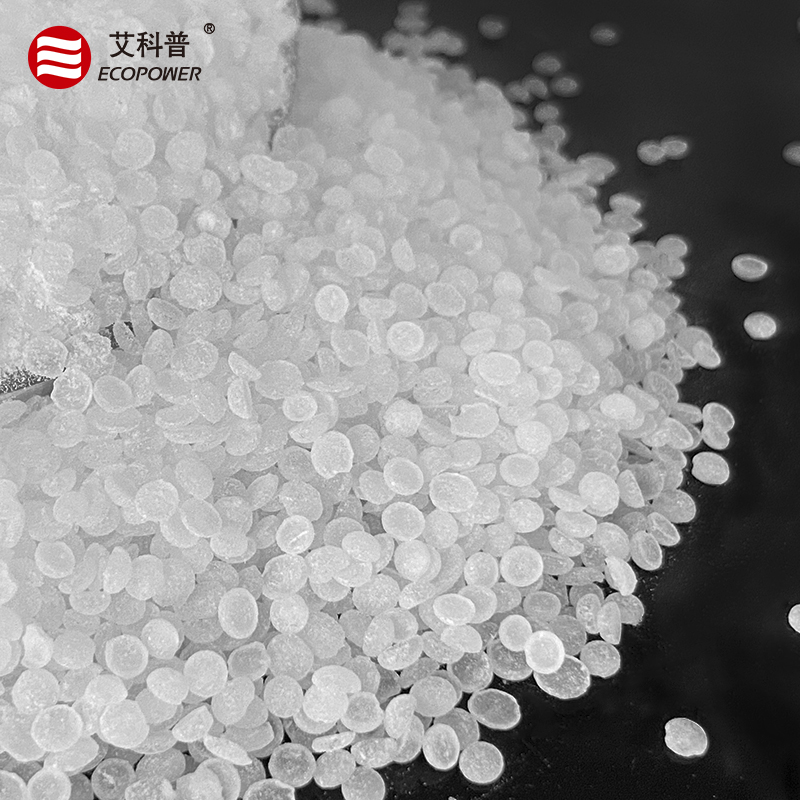

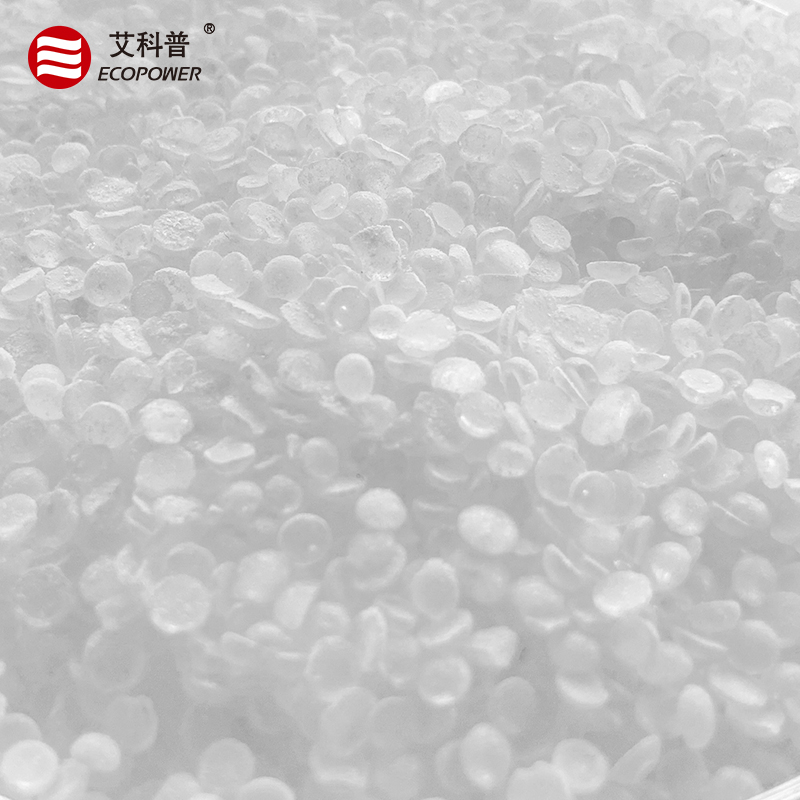

Hydrogenated Resin C9, Water White C9 resin

Type

HY 9100RM

Chemical Properties

HY 9100RM hydrocarbon is a water-white thermoplastic resin obtained from the collection and hydrogenation of C9 ingredients.

HY 9100RM hydrocarbon compound resin has nearly #0 color, without VOC and perfect stability.

Core Applications in Road Marking Coatings

1. Thermoplastic Road Marking Paint

HY-9100RM resin exhibits exceptional compatibility with petroleum asphalt and EVA wax systems, enabling the formulation of high-performance thermoplastic coatings. Key benefits include:

- Enhanced Weather Resistance: Withstands UV radiation, preventing yellowing and maintaining color vibrancy.

- Uniform Melting Behavior: Ensures smooth application at high temperatures (180–200°C) without smoke or decomposition.

- Improved Retroreflectivity: Transparent resin matrix protects glass beads (20–30% loading), extending nighttime visibility.

2. Solvent-Based Road Marking Paint

Ideal for fast-drying formulations, HY-9100RM resin offers:

- Rapid Solvent Release: Achieves surface drying in ≤5 minutes, minimizing traffic disruption.

- Strong Substrate Adhesion: Bonds securely to asphalt/concrete (≥3 MPa), resisting peeling under heavy traffic.

- Cold Climate Adaptability: Blends with elastic polymers (e.g., SBS) to prevent cracking at -20°C.

C9 hydrocarbon petroleum resins HY-9100RM for Technical Advantages to Road Marking

Property |

HY-9100RM Performance |

Industry Impact |

| UV Resistance | Gardener #0-1, no fading after 1,000h QUV | Extends marking lifespan by 30%+ |

| Thermal Stability | Softening point 95–110°C | Stable in hot-applied processes |

| Low Impurity | Ash ≤0.1%, acid value ≤1.0 mg KOH/g | Prevents coating defects & corrosion |

| Environmental Compliance | REACH compliant, no heavy metals | Meets global regulatory standards |

Packaging And Transportation

Packing: 25kg in PE bag or Paper bag. With pallet or without pallet.

Storage: Kept in a low temperature, dry and ventilated place, avoid direct sunlight.

Shelf life: One year in ventilating, cool and dry area.