Bookbinding Hot-Melt Adhesives

What is bookbinding hot melt adhesives

What is bookbinding hot melt adhesives

Bookbinding hot-melt adhesives are EVA hot-melt adhesives developed for the book-printing industry, including textbooks, magazine albums, notebooks, receipts, manuals, and bidding adhesives. The colors of bookbinding hot melt adhesives are milky white, transparent, light yellow, beige translucent, dark yellow, etc.

According to the application, there are side glue and back glue. The side glue is sticky to the cover. Generally, it needs to be softer than the adhesive. The color requirement is not high, but the viscosity requirement is high. Back glue has a slightly higher color requirement and a higher hardness.

Why hot melt is important in bookbinding

The tensile strength is usually 20-30kg/cm2. Hot melt adhesives must have good elongation. When the elongation at break is high, the toughness of the hot melt adhesive is good; only the good toughness can ensure that the book is not easy to be broken. The elongation is required to be greater than 300%.

An example composition is 30–40% of EVA copolymer (provides strength and toughness), 30–40% of tackifier resin (improves wetting and tack), 20–30% of wax (usually paraffin-based; reduces viscosity, alters setting speed, reduces cost), and 0.5–1.0% of stabilizers.[10] Fillers can be added for special applications. Can be formulated for service temperatures ranging from −40 to +80 °C, and for both short and long open times and a wide range of melt viscosities.

How to make hot melt have good solubility

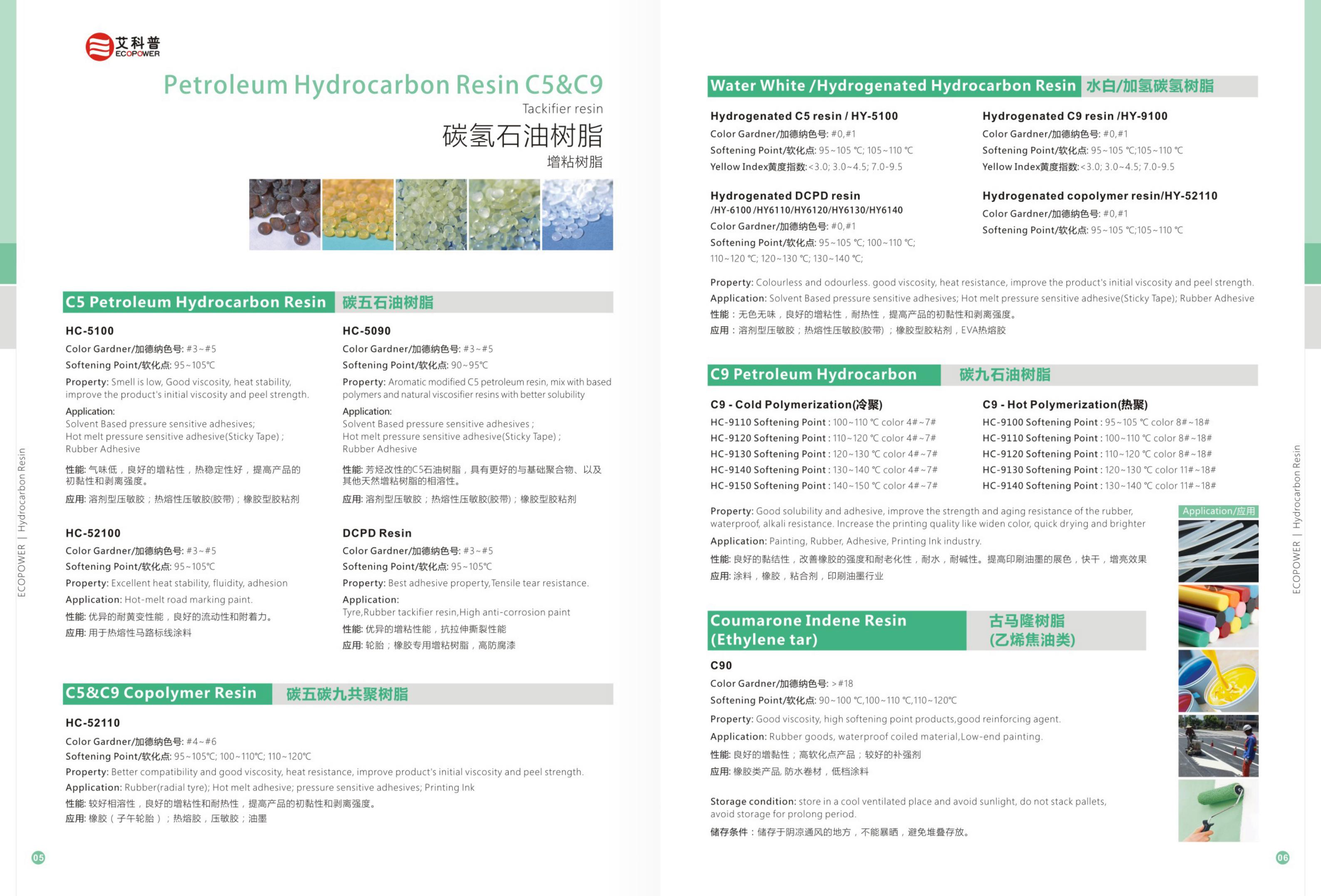

ECOPOWER Petroleum Hydrocarbon Resin is colourless and odourless.good viscosity,heat resistance,improve the product’s initial viscosity and peel strength.

| Ecopwerchem Product list(Petroleum Hydrocarbon Resin C5&C9) | |||||||

| Series | Product Type | Softening Point(oC) |

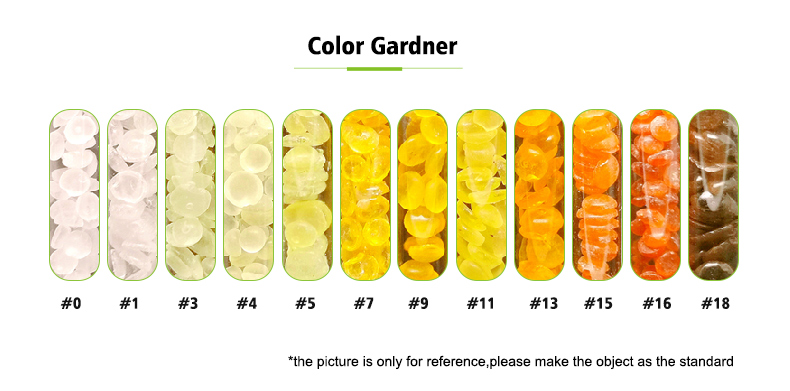

Color Gardner |

Acid Value | Ash cont≤% | Application | Memo |

| (mgKOH/g) | |||||||

| HYDROGENATED HYDROCARBON RESIN | HY-5100 | 95-105; 105-110 |

#0-1 | ≤1.0 | 0.1 | Solvent Based pressure sensitive adhesives Hot melt pressure sensitive adhesive |

Light color;Good ageing resistance: Keep the optimal balance between initial;viscidity, cohesion and peeling strength. |

| HY-9100 | 95-105; 105-110 |

#0-1 | ≤1.0 | 0.1 | |||

| HY-52110 | 95-105; 105-110 |

#0-1 | ≤1.0 | 0.1 | |||

| C5 PETROLEUM HYDROCARBON RESIN | HC-5100 | 95-105 | #3-5 | ≤1.0 | 0.1 | ||

| HC-51100 | 95-105 | #3-5 | ≤1.0 | 0.1 | Blend with styrene,good viscosity,heat stability.Increase the adhesive strength. | ||

| HC-53100 | 95-105 | #3-5 | ≤1.0 | 0.1 | EVA | blend with terpenes,higher viscosity,greatly improve the product’s initial viscosity | |

| C9 PETROLEUM HYDROCARBON | HC-9110 | 100-110 | #3-18 | ≤1.0 | 0.1 | Adhesive | Improve the glossiness,adhesive,hardness, resistance of acid on Paint. |

| HC-9120 | 110-120 | #3-18 | ≤1.0 | 0.1 | |||

Author:Elsa Peng(Sales Manager)

Mobile:+86-15014279449

E-Mail: sales02@ecopowerchem.com